Micro Tubular Coil Heaters

- Product Info

- Applications

- Ordering Information

- Technical Specification

Anupam Heaters Micro Tubular Coil Heater is a small, linear heating element that can be formed into different shapes and configurations. Also known as a Hot Runner Heater for its extensive use in Hot Runner Systems, the Micro Tubular Coil Heater is a high performance heater which allows high wattage in a limited space.

The ability to shape a Hot Runner Heater when cold enables to heat up parts with different shapes. During coiling, the gap between turns of coil can be modified to compensate for the heat losses at each end of the coil or to insert the heating element into slots.

Micro Tubular Coil Heater has a larger cross-sectional area and is thus capable of greater power than Micro Coil Heaters. For this reason the Hot Runner Heater is used in hot runners with adequate space and where high heat densities are required. Micro Tubular Coil Heater can accommodate type “J” or “K” thermocouple sensors.

Since the measurement point of a built-in thermocouple is situated in the Hot Runner Heater and never where the heat is actually required, our Micro Tubular Coil Heater with a thermocouple makes particular sense where the application allows the use of larger processing temperature or where the installation location or the design requires protection against overheating. The standard connection for our Micro Tubular Coil Heater is a 1000 mm PTFE-insulated lead wire with Fiberglass sleeve with protective earth conductor lead.

Construction

Anupam Heaters Micro Tubular Coil Heater feature precision wound parallel coil elements fusion welded to nickel cold pins. The element assemblies are embedded within high purity Magnesium Oxide Insulation and encased in Stainless Steel metal sheath. This Hot Runner Heater is swaged to the final rectangular, square or round cross-sectional dimensions to compact the internal core and High Purity insulation to near theoretical density. This high density construction maximizes heat transfer and dielectric properties and provides the high level of reliability and performance required for even the most demanding of applications.

The Hot Runner Heater is annealed after manufacturing, thus acquiring a high malleability that allows their being subsequently bent into any complex shape, with extremely narrow bending radius.

- Blow Molding Machine

- Extrusion Machine

- Hot Runner System

- Injection Molding Machine

- Thermoforming Machine

| ⚫ | - | - | 3.3 | 4 | - |

| ■ | - | - | 3 x 3 | 4 X 4 | - |

| ▅ | 1.8 X 3.2 | 2.5 X 4.2 | - | 4 X 6 | 4.6 X 8.6 |

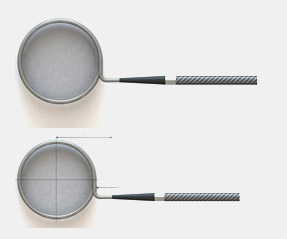

Axial Exit - Top & Side View

Radial Exit - Top View

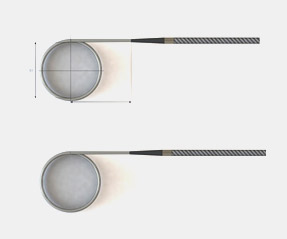

Tangential Exit - Front View

Tangential Exit - Top View

| Sr.No | Power @ 230 V | Heating Length (mm) | Cold Length (mm) |

| 1 | 250 W | 280 | 45 |

| 2 | 330 W | 400 | 50 |

| 3 | 400 W | 510 | 50 |

| 4 | 470 W | 600 | 50 |

| 5 | 500 W | 620 | 50 |

| 6 | 550 W | 720 | 50 |

| 7 | 650/700 W | 840 | 50 |

| 8 | 750 W | 1020 | 50 |

| 9 | 850 W | 1150 | 50 |

| 10 | 1000 W | 1400 | 50 |

| 11 | 1100 W | 1650 | 50 |

| 12 | 1200 W | 1800 | 50 |

| 13 | 1300 W | 1950 | 50 |

*More sizes available on request

Armour Cable

Braided Metal Sleeve

Fiberglass Sleeve

| Wattage | ± 10 % |

| Max. Sheath Temperature | 750 ° C / 1380 ° F |

| Insulation Resistance | ≥ 5 MΏ at 500V (DC) |

| Length Tolerance | ± 5% |

| Thermocouple | Type J / K |

| Diameter Tolerance | ± 0.15 mm |

| Max. Voltage | 250 V |

| High Voltage Test | 800 V (AC) |

| Max. Surface Load | 15 W/sq. cm or 100 W/sq. inch |

| Max. straight Length | 2500 mm |